|

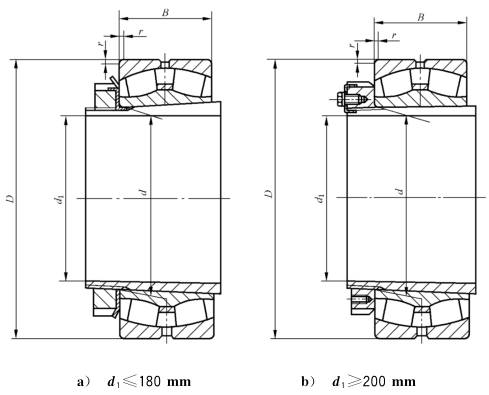

带紧定套调心滚子轴承 (GB/T 288—2013) |

||||||||||||||||||||||

|

带紧定套的调心滚子轴承20000K+H型 |

符号含义及应用 H—带紧定套 K—圆锥孔,锥度1:12 K30—圆锥孔,锥度1:30 能自动调心,主要承受径向载荷,同时也能承受双向轴向载荷。锥孔者,可装在紧定套或退卸套上,便于在光轴上或阶梯轴上任何位置安装,也可调整轴承的径向游隙。 应优先选用结构经优化设计的20000CC型和20000TN型产品。 |

|||||||||||||||||||||

|

基本尺寸 /mm |

基本额定 载荷/kN |

极限转速 /r·min-1 |

重量 /kg |

轴承代号 |

其他尺寸 /mm |

安装尺寸/mm |

计算系数 |

|||||||||||||||

|

d1 |

D |

B |

Cr |

C0r |

脂 |

油 |

W ≈ |

20000K+H型 |

d2 ≈ |

D2 ≈ |

B1 |

B2 ≈ |

r min |

da max |

db min |

Da max |

Ba min |

ra max |

e |

Y1 |

Y2 |

Y0 |

|

80 |

160 |

40 |

258 |

338 |

2400 |

3000 |

4.73 |

22218 K+H 318 |

107.8 |

141 |

65 |

18 |

2 |

107 |

96 |

150 |

10 |

2 |

0.24 |

2.9 |

4.3 |

2.8 |

|

|

160 |

52.4 |

338 |

482 |

1800 |

2400 |

6.1 |

23218 K +H 2318 |

105.5 |

137.2 |

86 |

18 |

2 |

105 |

99 |

150 |

18 |

2 |

0.31 |

2.2 |

3.2 |

2.1 |

|

|

190 |

43 |

328 |

420 |

1700 |

2200 |

7.52 |

21318 K+H 318 |

119.7 |

161 |

65 |

18 |

3 |

119 |

96 |

176 |

7 |

2.5 |

0.23 |

3.0 |

4.5 |

2.9 |

|

|

190 |

64 |

492 |

640 |

2200 |

2600 |

10.3 |

22318 K+H 2318 |

112.8 |

159.7 |

86 |

18 |

3 |

112 |

99 |

176 |

7 |

2.5 |

0.34 |

2.0 |

3.0 |

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

85 |

170 |

43 |

290 |

390 |

2200 |

2800 |

5.75 |

22219 K+H 319 |

113.5 |

148.5 |

68 |

19 |

2.1 |

113 |

102 |

158 |

9 |

2.1 |

0.24 |

2.8 |

4.2 |

2.7 |

|

|

200 |

45 |

365 |

485 |

1700 |

2200 |

8.7 |

21319 K+H 319 |

129.7 |

171.9 |

68 |

19 |

3 |

129 |

102 |

186 |

7 |

2.5 |

0.22 |

3.1 |

4.6 |

3.0 |

|

|

200 |

67 |

545 |

705 |

2000 |

2600 |

11.9 |

22319 K+H 2319 |

118.5 |

168.2 |

90 |

19 |

3 |

118 |

104 |

186 |

7 |

2.5 |

0.34 |

2.0 |

3.0 |

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90 |

165 |

52 |

330 |

510 |

1700 |

2200 |

— |

23120 K+H 3120 |

115.5 |

144.3 |

76 |

20 |

2 |

115 |

107 |

155 |

7 |

2 |

0.29 |

2.3 |

3.5 |

2.3 |

|

|

180 |

46 |

322 |

435 |

2200 |

2600 |

6.71 |

22220 K+H 320 |

120.3 |

158.1 |

71 |

20 |

2.1 |

120 |

108 |

168 |

8 |

2.1 |

0.24 |

2.8 |

4.1 |

2.7 |

|

|

180 |

60.3 |

432 |

630 |

1600 |

2200 |

8.67 |

23220 K +H 2320 |

118.6 |

154.5 |

97 |

20 |

2.1 |

118 |

110 |

168 |

19 |

2.1 |

0.32 |

2.1 |

3.2 |

2.1 |

|

|

215 |

47 |

395 |

530 |

1600 |

2000 |

10.5 |

21320 K+H 320 |

136.6 |

180.6 |

71 |

20 |

3 |

136 |

108 |

201 |

7 |

2.5 |

0.22 |

3.1 |

4.6 |

3.0 |

|

|

215 |

73 |

638 |

832 |

1900 |

2400 |

14.95 |

22320 K+H 2320 |

126.7 |

179.8 |

97 |

20 |

3 |

126 |

110 |

201 |

7 |

2.5 |

0.34 |

2.0 |

2.9 |

1.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

95 |

225 |

50 |

|

|

|

|

|

21321 K+H 321 |

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

180 |

56 |

388 |

602 |

1600 |

2000 |

7.61 |

23122 K+H 3122 |

126.4 |

157.9 |

81 |

21 |

2 |

126 |

117 |

170 |

7 |

2 |

0.29 |

2.4 |

3.5 |

2.3 |

|

|

200 |

53 |

420 |

588 |

1900 |

2400 |

9.52 |

22222 K+H 322 |

132.5 |

173.7 |

77 |

21 |

2.1 |

132 |

118 |

188 |

6 |

2.1 |

0.25 |

2.7 |

4.0 |

2.6 |

|

|

200 |

69.8 |

535 |

800 |

1500 |

1900 |

12.21 |

23222 K +H 2322 |

130.2 |

169.1 |

105 |

21 |

2.1 |

130 |

121 |

188 |

17 |

2.1 |

0.34 |

2.0 |

3.0 |

2.0 |

|

|

240 |

50 |

472 |

635 |

1400 |

1800 |

14 |

21322 K+H 322 |

150.5 |

200.5 |

77 |

21 |

3 |

150 |

118 |

226 |

9 |

2.5 |

0.21 |

3.2 |

4.8 |

3.1 |

|

|

240 |

80 |

735 |

968 |

1700 |

2200 |

20.25 |

22322 K+H 2322 |

140.9 |

199.6 |

105 |

21 |

3 |

140 |

121 |

226 |

7 |

2.5 |

0.34 |

2.0 |

3.0 |

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

110 |

180 |

46 |

308 |

500 |

1800 |

2200 |

5.68 |

23024 K +H 3024 |

133.5 |

162.2 |

72 |

22 |

2 |

133 |

127 |

170 |

7 |

2 |

0.23 |

2.9 |

4.4 |

2.9 |

|

|

200 |

62 |

462 |

722 |

1400 |

1800 |

10.24 |

23124 K+H 3124 |

140.1 |

175.1 |

88 |

22 |

2 |

140 |

128 |

190 |

7 |

2 |

0.29 |

2.4 |

3.5 |

2.3 |

|

|

215 |

58 |

492 |

690 |

1700 |

2200 |

11.65 |

22224 K+H 3124 |

143 |

187.9 |

88 |

22 |

2.1 |

143 |

128 |

203 |

11 |

2.1 |

0.26 |

2.6 |

3.9 |

2.6 |

|

|

215 |

76 |

625 |

955 |

1300 |

1700 |

14.9 |

23224 K +H 2324 |

141.5 |

182.7 |

112 |

22 |

2.1 |

141 |

131 |

203 |

17 |

2.1 |

0.34 |

2.0 |

3.0 |

2.0 |

|

|

260 |

86 |

868 |

1160 |

1500 |

1900 |

25.4 |

22324 K+H 2324 |

152.4 |

216.6 |

112 |

22 |

3 |

152 |

131 |

246 |

7 |

2.5 |

0.34 |

2.0 |

3.0 |

2.0 |