|

|

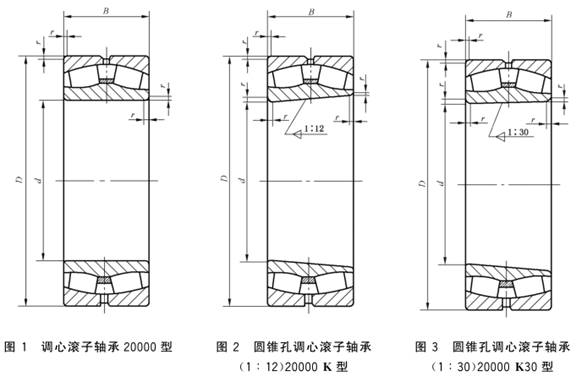

调心滚子轴承 (GB/T 288—2013) |

|||||||||||||||||||||

|

|

径向当量动载荷:当Fa/Fr≤e 时,Pr=Fr+Y1Fa 当Fa/Fr>e 时,Pr=0.67Fr+Y2Fa 径向当量静载荷:P0r=Fr+Y0Fa 符号含义及应用 CC—内圈无挡边,带活动中挡圈,冲压保持架,滚子和滚道经优化设计的结构,有助于滚子引导,减少摩擦发热 K—圆锥孔,锥度1:12 K30—圆锥孔,锥度1:30 W33—轴承外圈上有润滑油槽和三个油孔 TN—工程塑料成形保持架 能自动调心,主要承受径向载荷,同时也能承受双向轴向载荷。锥孔者,可装在紧定套或退卸套上,便于在光轴上或阶梯轴上任何位置安装,也可调整轴承的径向游隙。 应优先选用结构经优化设计的20000CC型和20000TN型产品。 |

|||||||||||||||||||||

|

基本尺寸/mm |

基本额定 载荷/kN |

极限转速 /r·min-1 |

重量 /kg |

轴承代号 |

其他尺寸 /mm |

安装尺寸/mm |

计算系数 |

|||||||||||||||

|

d |

D |

B |

Cr |

C0r |

脂 |

油 |

W ≈ |

20000 型 |

20000 K 型 |

20000 K30 型 |

d2 ≈ |

D2 ≈ |

B0 |

r min |

da min |

Da max |

ra max |

e |

Y1 |

Y2 |

Y0 |

|

|

20 |

52 |

15 |

31.5 |

31.2 |

6000 |

7500 |

0.175 |

21304 |

21304K |

|

29.5 |

42 |

— |

1.1 |

27 |

45 |

1 |

0.31 |

2.2 |

3.3 |

2.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

52 |

18 |

36.8 |

36.8 |

8000 |

10000 |

0.177 |

22205 |

22205K |

|

30.9 |

43.9 |

5.5 |

1 |

30 |

46 |

1 |

0.35 |

1.9 |

2.9 |

1.9 |

|

|

|

62 |

17 |

42.5 |

44.2 |

5300 |

6700 |

0.277 |

21305 |

21305K |

|

36.4 |

50.8 |

— |

1.1 |

32 |

55 |

1 |

0.29 |

2.4 |

3.5 |

2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

62 |

20 |

51.8 |

55.0 |

6700 |

8500 |

0.283 |

22206 |

22206K |

|

37.9 |

52.7 |

5.5 |

1 |

36 |

56 |

1 |

0.32 |

2.1 |

3.1 |

2.1 |

|

|

|

72 |

19 |

57.2 |

62.0 |

4500 |

6000 |

0.412 |

21306 |

21306K |

|

43.3 |

59.6 |

— |

1.1 |

37 |

65 |

1 |

0.27 |

2.5 |

3.7 |

2.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

35 |

72 |

23 |

70.2 |

79.0 |

5600 |

7000 |

0.437 |

22207 |

22207K |

|

44.1 |

60.9 |

5.5 |

1.1 |

42 |

65 |

1 |

0.32 |

2.1 |

3.2 |

2.1 |

|

|

|

80 |

21 |

65.2 |

73.2 |

4000 |

5300 |

0.542 |

21307 |

21307K |

|

49.1 |

66.3 |

— |

1.5 |

44 |

71 |

1.5 |

0.27 |

2.5 |

3.8 |

2.5 |

|

|

|

80 |

31 |

|

|

|

|

|

22307 |

22307K |

|

|

|

|

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

80 |

23 |

79.0 |

88.5 |

5000 |

6300 |

0.524 |

22208 |

22208K |

|

50.4 |

69.4 |

5.5 |

1.1 |

47 |

73 |

1 |

0.28 |

2.4 |

3.6 |

2.4 |

|

|

|

90 |

23 |

87.2 |

96.2 |

3600 |

4500 |

0.743 |

21308 |

21308K |

|

54.0 |

75.1 |

— |

1.5 |

49 |

81 |

1.5 |

0.26 |

2.6 |

3.8 |

2.5 |

|

|

|

90 |

33 |

122 |

138 |

4500 |

6000 |

1.02 |

22308 |

22308K |

|

51.4 |

74.3 |

5.5 |

1.5 |

49 |

81 |

1.5 |

0.38 |

1.8 |

2.7 |

1.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

45 |

85 |

23 |

82.8 |

95.2 |

4500 |

6000 |

0.571 |

22209 |

22209K |

|

54.6 |

73.6 |

5.5 |

1.1 |

52 |

78 |

1 |

0.26 |

2.6 |

3.8 |

2.5 |

|

|

|

100 |

25 |

102 |

115 |

3200 |

4000 |

1.0 |

21309 |

21309K |

|

61.4 |

84.4 |

— |

1.5 |

54 |

91 |

1.5 |

0.25 |

2.7 |

4.0 |

2.6 |

|

|

|

100 |

36 |

145 |

170 |

4000 |

5300 |

1.37 |

22309 |

22309K |

|

57.6 |

82.2 |

5.5 |

1.5 |

54 |

91 |

1.5 |

0.37 |

1.8 |

2.7 |

1.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

90 |

23 |

86.0 |

102 |

4300 |

5300 |

0.614 |

22210 |

22210K |

|

59.7 |

78.8 |

5.5 |

1.1 |

57 |

83 |

1 |

0.24 |

2.8 |

4.1 |

2.7 |

|

|

|

110 |

27 |

122 |

140 |

2800 |

3800 |

1.3 |

21310 |

21310K |

|

66.7 |

91.7 |

— |

2 |

60 |

100 |

2 |

0.25 |

2.7 |

4.0 |

2.6 |

|

|

|

110 |

40 |

182 |

212 |

3800 |

4800 |

1.79 |

22310 |

22310K |

|

63.4 |

91.9 |

5.5 |

2 |

60 |

100 |

2 |

0.37 |

1.8 |

2.7 |

1.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

55 |

100 |

25 |

105 |

125 |

3800 |

5000 |

0.847 |

22211 |

22211K |

|

66 |

88 |

5.5 |

1.5 |

64 |

91 |

1.5 |

0.24 |

2.8 |

4.2 |

2.8 |

|

|

|

120 |

29 |

145 |

170 |

2600 |

3400 |

1.65 |

21311 |

21311K |

|

72.6 |

100.5 |

— |

2 |

65 |

110 |

2 |

0.25 |

2.7 |

4.1 |

2.7 |

|

|

|

120 |

43 |

215 |

252 |

3400 |

4300 |

2.31 |

22311 |

22311K |

|

69.2 |

100.5 |

5.5 |

2 |

65 |

110 |

2 |

0.36 |

1.9 |

2.8 |

1.8 |

|

|

|

注:1.GB/T288已有新尺寸标注GB/T288-2013,新标准删除了原标准部分结构、紧定套相关尺寸和保持架代号。增加了38、39、40、49系列的外形尺寸,增加了22/23、系列密封轴承结构及其外形尺寸。本表数据结构符合《全国滚动轴承产品样本》第2版。 2.代号不包括结构变化附加代号,结构如有加油槽或油孔等变化,需与厂家联接。 |

|||||||||||||||||||||